Contract management plays an essential role in any organization’s purchasing cycle. Contracts provide the framework for relationships with suppliers, and evolve according to their own life cycle. Creation, negotiation, validation, signature, monitoring, analysis… these are all stages that can either boost performance or, on the contrary, slow it down, depending on the procedures in place within the company.

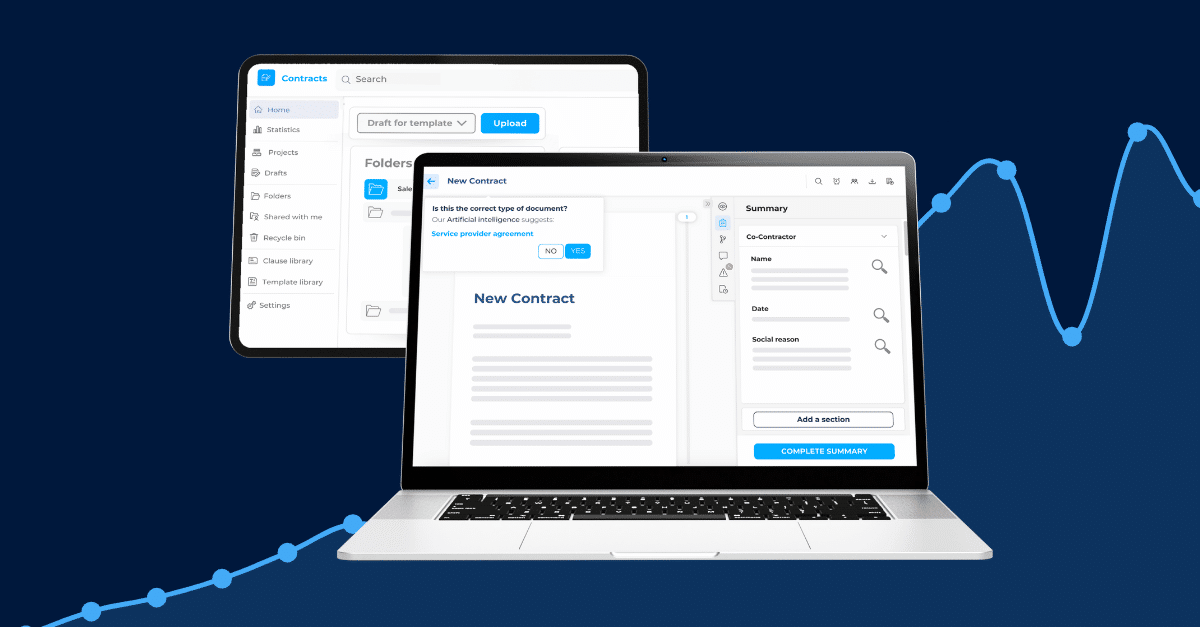

Good supplier contract management is therefore essential. However, it seems impossible when it’s done by hand or broken down into different, compartmentalized tools. This is where the use of a contract lifecycle management solution, also known as CLM (Contract Lifecycle Management), comes into its own for Purchasing Managers. Let’s take a look at how such technology and the associated best practices can improve the efficiency of purchasing processes.

Why dematerialize procurement contractual processes?

While manual contract management processes limit access to strategic information and impose repetitive, time-consuming tasks, their dematerialization contributes toachieving corporate performance objectives, while simplifying the day-to-day work of teams.

➙ Improve productivity

By automating collaborative contractualization processes, technology saves precious time for purchasing, legal and financial teams. Exchanges are much smoother, whether during the drafting of the contract or its amendments, during the internal review and approval process, or during the electronic signature process.

Find out more about electronic signatures

➙ Reduce costs

By making it easier to compare prices – and, more broadly, contractual conditions – and by reinforcing compliance, CLMs help to reduce supplier costs. In addition, the reduction in time spent on manual tasks thanks to their automation leads to a reduction in costs linked to the contract management process itself (which would represent an average of $6,900 according to a McKinsey & Company study). Finally, anticipating deadlines with monitoring and alert tools ensures that no obligation is missed, thus avoiding penalties and tacit renewals.

➙ Managing risks

A contract management solution provides a coherent view of all contracts, centralizing legal and financial information on suppliers in a single repository. What’s more, numerous functions make it easy to search, compare, export and visualize critical data, while highlighting risks that might otherwise go unnoticed.

Let’s take a look at 5 best practices for optimizing supplier contract management with a CLM.

1. Eliminate manual processes and editing errors

Comparing suppliers’ proposals and compiling them manually can be a very tedious task. A CLM solution enables companies to create their own centralized contract database and reference their document and clause templates. This repository of contractual data facilitates the drafting and comparison of conditions during contract negotiation, to select the best suppliers in line with company policy.

2. Streamline approval and signature processes

Internal approval workflows, or “digital sign-offs”, guarantee that the validation processes defined by the company will be respected. All the buyer has to do is launch a predefined workflow based on certain criteria: for example, CFO approval for a certain amount or type of document. The relevant approvers are automatically notified to validate, modify or reject the contract where appropriate. These workflows have a dual advantage: they speed up and secure approval processes prior to signature. Finally, the electronic signature applications integrated into a CLM solution enable purchase orders to be signed without leaving the platform, and within a very short time.

3. Monitor obligations during contract performance

Modifications, deliverables, renewals, terminations, payment windows, performance targets… these are all sources of risk that are well known when contracts are signed, but often lost sight of during execution. By scheduling reminders for key contract milestones, you can “forget” these obligations with complete peace of mind: a CLM solution notifies the users concerned as the deadline approaches.

4. Assess legal and financial risks

Contracts are an invaluable source of data for the business: analyzing them enables hidden risks to be effectively assessed, so that the right decisions can be taken. But you need access to the right information, when you need it… and that’s where CLM comes in.

A multi-criteria search engine capable of cross-referencing searches by keywords and metadata (=type of clause, dates, amounts…) enables the documents concerned to be found instantly. Exporting important information to Excel gives a 360° view of the commitments made. In just a few clicks, the user can extract and sort suppliers according to price, geographical zone, risk clause, date of termination, etc.

Highlighting risky clauses in documents is also an asset for identifying the risk level of current commitments.

Finally, contractual summary sheets highlight important contractual data without having to go through the entire document.

5. Analyze supplier performance

Good visibility of the performance of supplier relationships is one of the keys to optimizing the management of these partners and of SLAs. A CLM solution structures contractual data and enables conditions to be monitored: dates, amounts, supplier types, contract types, security, commitment and termination clauses, or even, in the context of the pandemic, force majeure and related risk clauses… Nothing escapes the control of the purchasing department. With real-time information, organizations can know which suppliers are fulfilling their obligations, and can manage them accordingly.

Within the CLM, dashboards and their customizable graphics enable you to visualize the performance and evolution of activity linked to supplier contracts. They provide clear KPIs for decision-making.

Want to see our CLM in action?